Products

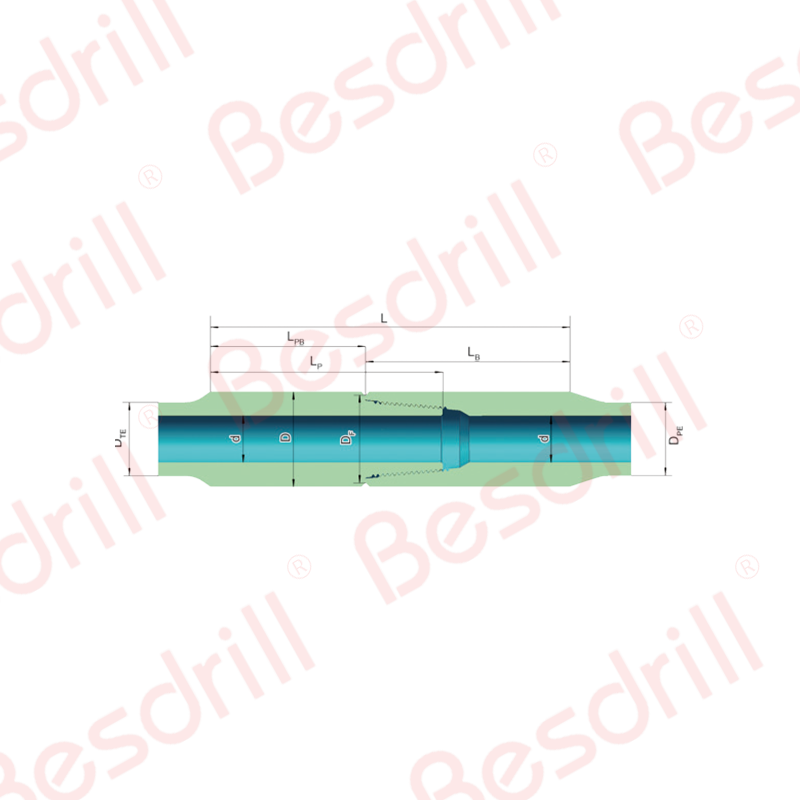

DRILL COLLAR-STANDARD AND SPIRAL

- Type:Drill pipe

- CAS No:

- Qty in 20' FCL:

- Min. Order:

- Packaging:

-

Number and connection table

Outside Diameter

Inside Diameter

Length

mm

Belvel Diameter

Mm

Bending

Strength

Ratio

mm

In

mm

in

NC23-31

79.4

3 1/8

31.8

1 1/2

9150

76.2

2.57:1

NC26-35(2 3/8 IF)

88.9

3 1/2

38.1

1 1/2

9150

82.9

2.42:1

NC31-41(2 7/8 IF)

104.8

4 1/8

50.8

2

9150

100.4

2.43:1

NC35-47

120.6

4 3/4

50.8

2

9150

114.7

2.58:1

NC38-50(3 1/2IF)

127

5

57.2

2 1/4

9150

121

2.38:1

NC44-60

152.4

6

57.2

2 1/4

9150 or 9450

144.5

2.49:1

NC44-60

152.4

5

71.4

2 13/16

9150 or 9450

144.5

2.84:1

NC44-62

158.8

6 1/4

57.2

2 1/4

9150 or 9450

149.2

2.91:1

NC44-62(4IF)

158.8

6 1/2

71.4

2 13/16

9150 or 9450

150

2.63:1

NC44-65(4IF)

165.1

6 1/2

57.2

2 1/4

9150 or 9450

154.8

2.76:1

NC44-65(4IF)

165.1

6 1/2

71.4

2 13/16

9150 or 9450

154.8

3.05:1

NC44-67(4IF)

171.4

6 3/4

57.2

2 1/4

9150 or 9450

159.5

3.18:1

NC50-672(4 1/2IF)

171.4

6 3/4

71.4

2 13/16

9150 or 9450

159.5

2.37:1

NC50-70(4 1/2IF)

177.8

7

57.2

2 1/4

9150 or 9450

164.7

2.54:1

NC50-70(4 1/2IF)

177.8

7

71.4

2 13/16

9150 or 9450

164.7

2.73:1

NC50-72(4 1/2IF)

184.2

7 1/4

71.4

2 13/16

9150 or 9450

169.5

3.21:1

NC56-77

196.8

7 3/4

71.4

2 13/16

9150 or 9450

185.3

2.70:1

NC56-80

203.2

8

71.4

2 13/16

9150 or 9450

190.1

3.02:1

6 5/8REG

209.6

8 1/4

71.4

2 13/16

9150 or 9450

195.7

2.93:1

NC61-90

228.6

9

71.4

2 13/16

9150 or 9450

212.7

3.17:1

7 5/8 REG

241.3

9 1/2

76.2

3

9150 or 9450

223.8

2.81:1

NC70-97

247.6

9 3/4

76.2

3

9150 or 9450

232.6

2.57:1

NC70-100

254

10

76.2

3

9150 or 9450

237.3

2.81:1

8 5/8 REG

279.4

11

76.2

3

9150 or 9450

266.7

2.84:1

Slips and elevator grooves can be produced upon the customers' requirement.

-

Drill Collar is the basic component in the BHA which provides weight on the bit for drilling and keeps the drillsting in tension.

TIANHE Drill Collar has been approved by the NS-1 certification, it is manufactured from 4145H modified quenched and tempered steel, strict metallurgical specifications are followed to insure that full length heat treating produces a consistent maximum depth of hardness.

Features and Benefits

●A hardness range of 285 to 341 BHN and a Charpy impact value of 40 ft-lbs are guaranteed at evenly distributed 16 points in any sections at room temperature;

● Connections are completed(phosphate coated)to protect them from the elements after machining and to help prevent galling upon initial make-up;

● Thread roots are cold rolled on API and H-90 connections;

● Pressed steel thread protectors are supplied for all drill collar that are equipped with standard connections When ordering Please specify;

● Drill collar OD and ID;

● Overall length;

● Connections required (size and type);

● Special features desired, for example:

Slick or Spiral;

Stress Relief Features;

Slip and/or Elevator Recess;

Hardbanding;

- The industry today faces a major risk of Time and Resource bound execution of Projects. With its unique and Client centric approach towards Project Management, OMCI RIG TECH provides its Clients with the means to completely eliminate this Risk. What differentiates us from others is our willingness to walk-the-extra-step to meet and surpass the Client’s expectations. Project management for us is about Execution and making it happen. The industry today faces a major risk of Time and Resource bound execution of Projects. With its unique and Client centric approach towards Project Management, OMCI RIG TECH provides its Clients with the means to completely eliminate this Risk. What differentiates us from others is our willingness to walk-the-extra-step to meet and surpass the Client’s expectations. Project management for us is about Execution and making it happen. The industry today faces a major risk of Time and Resource bound execution of Projects. With its unique and Client centric approach towards Project Management, OMCI RIG TECH provides its Clients with the means to completely eliminate this Risk. What differentiates us from others is our willingness to walk-the-extra-step to meet and surpass the Client’s expectations. Project management for us is about Execution and making it happen.

- The industry today faces a major risk of Time and Resource bound execution of Projects. With its unique and Client centric approach towards Project Management, OMCI RIG TECH provides its Clients with the means to completely eliminate this Risk. What differentiates us from others is our willingness to walk-the-extra-step to meet and surpass the Client’s expectations. Project management for us is about Execution and making it happen. The industry today faces a major risk of Time and Resource bound execution of Projects. With its unique and Client centric approach towards Project Management, OMCI RIG TECH provides its Clients with the means to completely eliminate this Risk. What differentiates us from others is our willingness to walk-the-extra-step to meet and surpass the Client’s expectations. Project management for us is about Execution and making it happen.